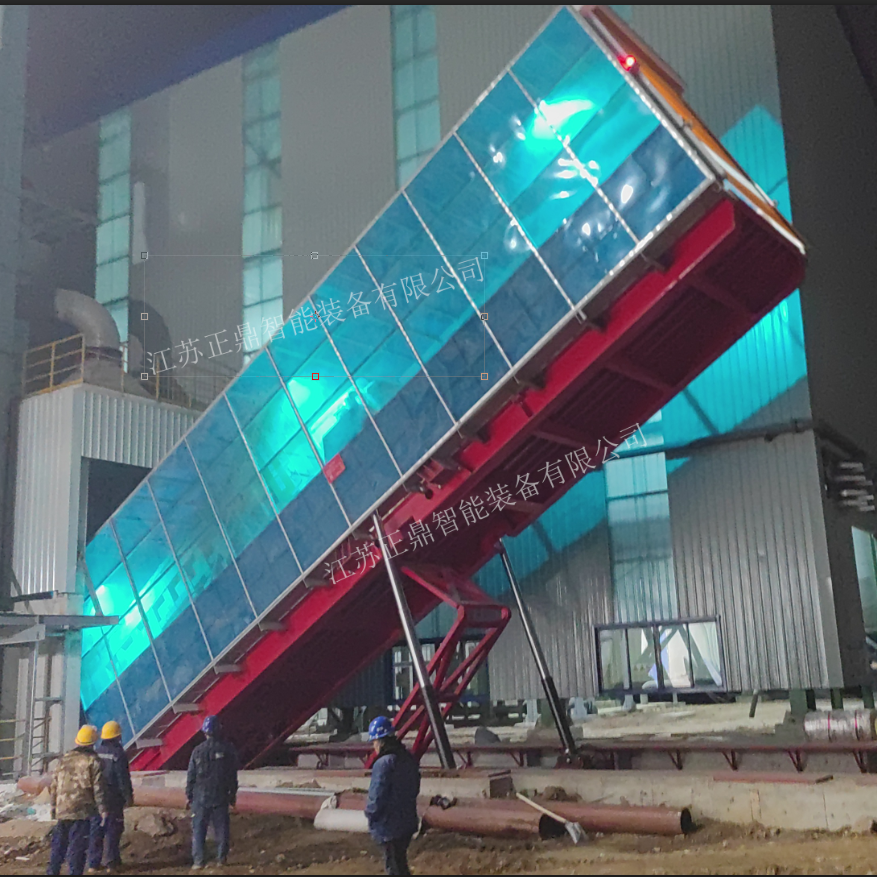

truck bed roller unloader

A truck bed roller unloader represents a revolutionary solution in material handling and cargo management. This innovative system consists of a series of powered rollers integrated into the truck bed, designed to efficiently load and unload cargo with minimal manual intervention. The system typically features heavy-duty rollers manufactured from durable materials like steel or high-strength polymers, powered by an electric or hydraulic motor system. These rollers are strategically positioned across the truck bed's surface, creating a seamless conveyor-like mechanism. The control system allows for both forward and reverse operation, enabling precise cargo movement in either direction. Advanced models incorporate variable speed controls, safety lockouts, and emergency stop features. The system can handle various cargo types, from palletized goods to loose materials, with weight capacities ranging from 1,000 to 10,000 pounds depending on the model. Modern truck bed roller unloaders often include smart features such as load sensing technology, automated spacing control, and digital monitoring systems to ensure optimal performance and safety.