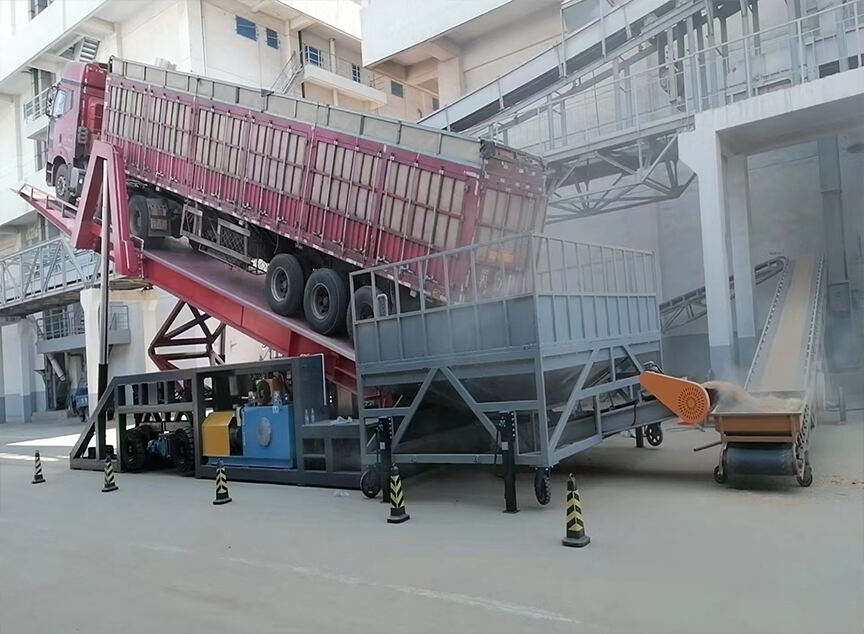

Sa kasalukuyang mabilis na industriyal na kapaligiran, napakahalaga ng epektibong mga solusyon sa paghawak ng materyales upang mapanatili ang mapagkumpitensyang operasyon. Ang isang truck unloader ay kumakatawan sa isang rebolusyonaryong paraan upang mapadali ang proseso ng pag-unload ng karga, na nag-aalis sa pangangailangan ng manu-manong paggawa at malaki ang pagbawas sa oras ng hindi pagpapatakbo. Ang mga sopistikadong sistemang ito ay nagbago sa paraan ng paghawak ng mga negosyo sa mga bulk na materyales, na nag-aalok ng walang kapantay na antas ng kahusayan at kaligtasan sa mga operasyon ng logistics.

Ang mga modernong pasilidad sa industriya ay nangangailangan ng kagamitan na kayang umangkop sa iba't ibang pangangailangan sa operasyon habang patuloy na pinapanatili ang pare-parehong pamantayan ng pagganap. Ang mga mobile truck unloader system ay mahusay sa aspetong ito, na nagbibigay ng kakayahang umangkop na hindi kayang tugunan ng mga permanenteng instalasyon. Maaaring ilipat ang mga yunit na ito kung kinakailangan, kaya mainam sila para sa mga pasilidad na may maramihang loading zone o seasonal na pagbabago sa operasyon. Ang kadaliang makaalis ay tinitiyak ang pinakamataas na kita sa pamumuhunan dahil nagagamit ang isang kagamitan sa iba't ibang pangangailangan sa loob ng magkakaibang lokasyon ng pasilidad.

Mga Advanced na Katangian sa Engineering ng Modernong Sistema

Mga Hydraulic Power System at Mekanismo ng Kontrol

Ang mga hydraulic power system na naisama sa modernong disenyo ng truck unloader ay kumakatawan sa pinakamodernong kahusayan sa inhinyeriya. Ginagamit ng mga sistemang ito ang mga advanced na konpigurasyon ng balbula at teknolohiya sa pamamahala ng presyon upang magbigay ng tumpak na kontrol sa mga operasyon ng pag-angat. Ang mga high-performance na hydraulic pump ay lumilikha ng pare-parehong output ng presyon, tinitiyak ang maayos at maaasahang operasyon kahit sa ilalim ng mahigpit na kondisyon ng karga. Pinapayagan ng mga sopistikadong mekanismo ng kontrol ang mga operator na i-tune ang bilis ng pag-angat at katumpakan ng posisyon, na umaangkop sa iba't ibang uri ng karga at mga kinakailangan sa pag-unload.

Ang mga advanced na sistema ng pressure relief ay nagpoprotekta sa mga bahagi ng kagamitan laban sa pinsala habang pinananatili ang mga pamantayan sa kaligtasan ng operasyon. Ang mga variable displacement pump ay awtomatikong nag-aadjust ng output batay sa mga pangangailangan ng karga, upang ma-optimize ang pagkonsumo ng enerhiya at bawasan ang mga gastos sa operasyon. Ang mga electronic control interface ay nagbibigay ng real-time na monitoring capabilities, na nagpapakita ng status ng system, timbang ng karga, at mga sukatan ng performance. Ang mga tampok na ito ay nagbibigay-daan sa maagang pagpaplano ng maintenance at tumutulong na maiwasan ang mapaminsalang pagkabigo ng kagamitan sa pamamagitan ng maagang pagtukoy sa mga potensyal na isyu.

Disenyo ng Istruktura at Pamamahagi ng Carga

Ang balangkas na estruktura ng mga modernong sistema ng truck unloader ay gumagamit ng mataas na lakas na konstruksyon na bakal na may mga estratehikong punto ng palakas. Dinisenyo ng mga inhinyero ang mga sistemang ito gamit ang advanced na finite element analysis upang i-optimize ang distribusyon ng karga at bawasan ang pagkumpol ng tensyon. Ang disenyo ng plataporma ay nakakatugon sa iba't ibang konpigurasyon ng trak habang pinapanatili ang integridad ng istraktura sa ilalim ng pinakamataas na rated na karga. Ang mga espesyalisadong sistema ng bearing at mga punto ng pag-ikot ay nagsisiguro ng maayos na operasyon habang pantay na ipinamamahagi ang puwersa sa buong istraktura.

Ang mga safety margin na isinama sa mga structural calculation ay lumalampas sa mga industry standard, na nagbibigay tiwala sa long-term reliability. Ang mga corrosion-resistant coating at pagpili ng materyales ay pinalawig ang lifespan ng kagamitan sa mahihirap na industrial environment. Ang modular design principles ay nagbibigay-daan sa madaling maintenance access at pagpapalit ng component, na binabawasan ang downtime at service costs. Ang engineering excellence na nakikita sa mga sistemang ito ay sumasalamin sa maraming dekada ng pagpapaunlad sa mobile material handling technology.

Kahusayan sa Operasyon at Mga Benepisyo sa Pagganap

Pagbawas ng Oras at Pagpapahusay ng Produktibidad

Ang pagpapatupad ng isang sistema ng truck unloader ay malaki ang nagpapabawas sa oras ng pagbaba ng karga kumpara sa tradisyonal na paraan na manual. Ang awtomatikong pagpo-posisyon at mga mekanismo ng pag-aangat ay nagtatanggal sa oras na kinakailangan sa manu-manong paghawak ng karga, na nagbibigay-daan sa mga trak na matapos ang operasyon ng pagbaba sa ilang minuto imbes na oras. Ang ganitong pagpapabuti sa kahusayan ay direktang naghahantong sa mas mataas na kapasidad ng throughput at mas mababang gastos sa paggawa. Ang mga pasilidad ay nakakapagproseso ng mas malaking bilang ng mga sasakyan bawat shift, pinapataas ang potensyal na kita at pinalulugod ang mga customer sa pamamagitan ng mas mabilis na oras ng pagpoproseso.

Ang pare-parehong bilis ng operasyon at maasahang mga oras ng kiklo ay nagbibigay-daan sa mas mahusay na pagpaplano at paglalaan ng mga mapagkukunan. Ang mga tagapamahala ng armada ay maaaring i-optimize ang iskedyul ng paghahatid batay sa tiyak na pagtataya ng oras ng pag-unload, na nagpapabuti sa kabuuang kahusayan ng logistika. Ang pagiging maaasahan ng mga awtomatikong sistema ay binabawasan ang pagbabago sa operasyon, na nagpapadali sa pagpapanatili ng pare-parehong antas ng serbisyo. Ang mas pinahusay na mga sukatan ng produktibidad ay nagpapakita ng malinaw na balik sa pamumuhunan sa pamamagitan ng pagpapabuti ng kapasidad ng operasyon at pagbaba sa gastos ng paghawak bawat yunit.

Pagbawas sa Gastos sa Paggawa at Pagpapabuti sa Kaligtasan

Ang operasyon ng automated truck unloader ay nagpapababa nang malaki sa pangangailangan sa lakas-paggawa habang pinahuhusay ang kalagayan ng kaligtasan sa lugar ng trabaho. Ang tradisyonal na paraan ng manu-manong pag-ubos ay naglalantad sa mga manggagawa sa paulit-ulit na mga pinsala at potensyal na panganib sa kaligtasan dulot ng pagbubuhat ng mabigat. Tinatanggal ng mga automated system ang mga panganib na ito sa pamamagitan ng pag-alis sa tao mula sa pisikal na proseso ng pag-ubos. Ang mga single-operator control system ay pumapalit sa mga multi-person na grupo ng manu-manong pag-ubos, kaya nababawasan ang gastos sa lakas-paggawa habang nananatili o lumalakas ang kahusayan ng operasyon.

Ang pagpapahusay sa kaligtasan ay lumalawig pa sa pag-iwas sa mga aksidente, kabilang ang pagbaba sa gastos sa insurance at mga benepisyo sa pagsunod sa regulasyon. Isinasama ng mga automated system ang maraming tampok para sa kaligtasan tulad ng emergency stops, pagmomonitor sa bigat ng karga, at fail-safe mechanism. Tinitiyak ng mga tampok na ito ang ligtas na operasyon habang natutugunan o nilalampasan ang mga alituntunin sa kaligtasan sa trabaho. Dahil sa maasahan at nakaplanong operasyon ng mga automated system, nababawasan ang posibilidad ng aksidente at nalilikha ang mas kontroladong kapaligiran sa trabaho para sa lahat ng tauhan sa pasilidad.

Kababalaghan at Alakhan ng Pagpapatakbo

Multi-Industriya Mga Aplikasyon at Kakayahang Umangkop

Ang pagiging maraming gamit ng mga mobile truck unloader system ay nagiging angkop para sa iba't ibang aplikasyon sa industriya sa kabuuan ng maraming sektor. Ginagamit ng mga operasyong agrikultural ang mga sistemang ito para sa epektibong pag-unload ng butil at patuka, samantalang nakikinabang ang mga kumpanya sa konstruksyon sa mabilis na pag-unload ng mga aggregate at materyales. Ginagamit naman ng mga pasilidad sa pagmamanupaktura ang teknolohiya ng truck unloader para sa paghawak ng hilaw na materyales, upang bawasan ang mga pagkaantala sa proseso at mapanatili ang pare-parehong iskedyul ng produksyon. Ang kakayahang umangkop ng mga sistemang ito ay nagbibigay-daan sa pag-customize batay sa tiyak na pangangailangan ng industriya at uri ng karga.

Ang mga operasyon sa pamamahala ng basura ay nakakakita ng malaking halaga sa awtomatikong pag-unload para sa epektibong operasyon ng mga trak sa pagtatapon. Ginagamit ng mga operasyong pangmina ang matitibay na sistema ng truck unloader para sa mga aplikasyon sa pagpoproseso ng ore at mineral. Nakikinabang ang mga pasilidad sa pagproseso ng pagkain mula sa sanitary designs na sumusunod sa mahigpit na pamantayan sa kalinisan habang pinapanatili ang kahusayan sa operasyon. Ipinapakita ng malawak na saklaw ng aplikasyon ang universal na halaga ng teknolohiyang awtomatikong pag-unload sa iba't ibang sektor ng industriya.

Mga Opsyon sa Pagpapasadya at Teknikal na Detalye

Modernong truck unloader ang mga tagagawa ay nag-aalok ng malawak na mga opsyon sa pagpapasadya upang matugunan ang tiyak na mga pangangailangan sa operasyon. Ang mga load capacity specifications ay mula sa light-duty applications hanggang sa heavy industrial systems na kayang magproseso ng maximum truck weights. Maaaring i-customize ang sukat ng platform upang akmatin ang iba't ibang configuration ng trak at laki ng cargo container. Ang hydraulic system specifications ay maaaring i-adjust batay sa kinakailangang bilis ng pag-angat at katumpakan sa posisyon.

Ang mga opsyon sa control system ay kinabibilangan ng manu-manong, semi-awtomatikong, at ganap na awtomatikong mga mode ng operasyon upang tugma sa antas ng automation ng pasilidad. Ang mga espesipikasyon sa kapaligiran ay tumutugon sa mga saklaw ng temperatura, paglaban sa kahalumigmigan, at mga kinakailangan sa kompatibilidad sa kemikal. Kasama sa mga opsyonal na tampok ang mga kakayahan sa remote monitoring, mga sistema ng data logging, at integrasyon sa mga umiiral nang sistema sa pamamahala ng pasilidad. Tinitiyak ng mga pasadyang opsyon na ito ang optimal na pagganap sa tiyak na mga kapaligiran at aplikasyon sa operasyon.

Mga Pag-iisip Tungkol sa Pag-install at Pag-aalaga

Paghahanda ng Lokasyon at Mga Kailangan sa Pag-install

Ang maayos na paghahanda sa lugar ay tinitiyak ang optimal na pagganap at haba ng buhay ng mga instalasyon ng truck unloader. Nag-iiba ang mga kinakailangan sa pundasyon batay sa mga espesipikasyon ng sistema at kondisyon ng lupa, kung saan nagbibigay ang mga concrete pad ng matatag na mounting surface. Dapat sapat ang imprastrakturang elektrikal upang mapagkasya ang mga pangangailangan sa kuryente para sa mga hydraulic system at control panel. Ang sapat na mga sistema ng drainage ay pinipigilan ang pagtambak ng tubig sa paligid ng mga pundasyon ng kagamitan, na nagpoprotekta sa mga bahagi laban sa pinsalang dulot ng kahalumigmigan.

Isinasaalang-alang ng pagpaplano ng pag-install ang mga daloy ng operasyon at ligtas na espasyo sa paligid ng kagamitan. Dapat masakop ng mga daanan ang parehong galaw ng trak at pangangailangan ng sasakyang pantulong sa pagmamintra. Ang mga koneksyon sa utilities tulad ng kuryente, nakapipigil na hangin, at mga sistema ng komunikasyon ay nangangailangan ng maingat na koordinasyon habang nag-i-install. Tinitiyak ng mga propesyonal na serbisyo sa pag-install ang pagsunod sa mga regulasyon sa kaligtasan at mga tukoy ng tagagawa para sa saklaw ng warranty.

Preventive Maintenance at Mga Kinakailangan sa Serbisyo

Pinapataas ng regular na programa ng pag-iingat ang katiyakan ng kagamitan at binabawasan ang haba ng operasyon nito. Kasama sa pagmamintra sa hydraulic system ang pagsusuri sa fluid, pagpapalit ng filter, at iskedyul ng inspeksyon sa seal. Ang mga programa sa paglalagay ng lubricant sa mga bahaging mekanikal ay maiiwasan ang maagang pagkasira at tinitiyak ang maayos na operasyon. Saklaw ng pagmamintra sa electrical system ang paglilinis ng control panel, pagpapatigas ng mga koneksyon, at mga pamamaraan ng pagtutuos ng sensor.

Ang mga nakatakdang inspeksyon ay nakikilala ang mga potensyal na isyu bago ito magresulta sa pagkabigo ng kagamitan o mga panganib sa kaligtasan. Ang mga iskedyul ng pagpapalit ng sangkap batay sa oras ng operasyon at mga siklo ng karga ay tumutulong sa pagpapanatili ng optimal na pagganap. Ang mga programa ng pagsasanay para sa mga tauhan sa pagpapanatili ay nagagarantiya ng tamang prosedurang serbisyo at pagsunod sa kaligtasan. Ang komprehensibong talaan ng pagpapanatili ay sumusuporta sa mga reklamo sa warranty at tumutulong sa pag-optimize ng mga interval ng serbisyo batay sa aktuwal na kondisyon ng operasyon.

FAQ

Ano ang mga salik na nagdedetermina sa angkop na kapasidad ng truck unloader para sa aking pasilidad

Ang pagpili ng kapasidad ng truck unloader ay nakadepende sa ilang mahahalagang salik kabilang ang maximum na bigat ng trak, pang-araw-araw na kinakailangan sa throughput, at uri ng kargamento na hinahandle. Isaalang-alang ang pinakamabigat na trak na regular na pinapagana sa iyong pasilidad at idagdag ang angkop na safety margin. Suriin ang peak demand periods upang matiyak ang sapat na kapasidad sa panahon ng masikip na operasyon. Isama ang mga projection sa hinaharap na paglago upang maiwasan ang maagang limitasyon ng kapasidad habang lumalawak ang operasyon.

Paano nakaaapekto ang panahon sa operasyon ng mobile truck unloader

Ang mga disenyo na lumalaban sa panahon ay nagbibigay-daan sa operasyon ng truck unloader sa karamihan ng mga kondisyon sa kapaligiran, bagaman maaaring kailanganin ang pagbabago sa operasyon sa matinding panahon. Ang ulan at niyebe ay maaaring makaapekto sa traksyon at visibility, na nangangailangan ng karagdagang mga pag-iingat sa kaligtasan habang nasa operasyon. Ang matinding temperatura ay maaaring makaapekto sa pagganap ng hydraulic fluid, na nangangailangan ng pagpapalit ng fluid depende sa panahon o mga sistema ng pag-init. Ang mga kondisyon ng hangin na lampas sa mga espesipikasyon ng tagagawa ay maaaring mangailangan ng pagtigil sa operasyon dahil sa kaligtasan.

Anong mga sertipikasyon sa kaligtasan ang dapat hanapin ko sa mga sistema ng truck unloader

Hanapin ang mga sistema ng truck unloader na sumusunod sa mga nauukol na pamantayan sa kaligtasan ng industriya kabilang ang pagsunod sa OSHA at CE marking para sa internasyonal na operasyon. Ang mga sertipikasyon ng hydraulic system ay nagsisiguro sa kaligtasan ng pressure vessel at tamang pamantayan sa inhinyeriya. Ang mga sertipikasyon ng electrical system ay nagpapatunay sa ligtas na pag-install at proseso ng operasyon sa kuryente. Ang mga sertipikasyon sa kalidad ng produksyon tulad ng mga pamantayan ng ISO ay nagpapakita ng pare-parehong proseso sa produksyon at mga hakbang sa kontrol ng kalidad.

Maari bang i-retrofit ang mga umiiral na pasilidad ng mga sistema ng truck unloader nang walang malalaking pagbabago

Maraming umiiral na pasilidad ang kayang magpatupad ng mga retrofit para sa truck unloader nang may kaunting pagbabago sa istraktura sa pamamagitan ng maingat na pagpili at pagpaplano ng sistema. Ang mga mobile system ay nag-aalok ng partikular na mga kalamangan para sa mga aplikasyon ng retrofit dahil sa kanilang kakayahang umangkop at mas mababang pangangailangan sa pundasyon. Ang mga site survey ay nakikilala ang mga potensyal na hamon sa pag-install at mga kinakailangang pagbabago bago pa man ang pagpili ng kagamitan. Ang mga propesyonal na koponan sa pag-install ay kadalasang kayang gumawa sa paligid ng umiiral na imprastruktura upang minumin ang pagkakaubos ng pasilidad habang nagtatayo.

Talaan ng mga Nilalaman

- Mga Advanced na Katangian sa Engineering ng Modernong Sistema

- Kahusayan sa Operasyon at Mga Benepisyo sa Pagganap

- Kababalaghan at Alakhan ng Pagpapatakbo

- Mga Pag-iisip Tungkol sa Pag-install at Pag-aalaga

-

FAQ

- Ano ang mga salik na nagdedetermina sa angkop na kapasidad ng truck unloader para sa aking pasilidad

- Paano nakaaapekto ang panahon sa operasyon ng mobile truck unloader

- Anong mga sertipikasyon sa kaligtasan ang dapat hanapin ko sa mga sistema ng truck unloader

- Maari bang i-retrofit ang mga umiiral na pasilidad ng mga sistema ng truck unloader nang walang malalaking pagbabago