Key Factors to Consider When Choosing Truck Unloading Equipment

Load Type and Weight Capacity Requirements

Picking out truck unloading gear depends heavily on what kind of stuff needs moving around and how much weight we're talking about. First things first, figure out exactly what sort of goods pass through regularly - maybe standard pallets, loose bulk stuff, or those awkward oversized shipments that always seem to cause problems. Knowing the weight limits for different machines matters because nobody wants their operation grinding to a halt mid-job or worse, creating safety hazards. Most good quality equipment should handle pretty much anything thrown at it, but there are exceptions when dealing with delicate glassware or oddly shaped machinery parts. Industry specs do exist for load capacities depending on material type, so taking a look at those numbers makes sense before making any final decisions.

Facility Layout and Dock Configuration

When selecting truck unloading gear, looking at facility layout and dock setup matters a lot. Space matters everywhere from door dimensions to ceiling clearances since these physical constraints determine what kind of equipment actually fits. Loading dock arrangements matter too because accessibility issues can really limit options while affecting day-to-day operations. Workflow impact needs serious consideration against current infrastructure limitations. Good equipment choices should boost productivity without creating traffic jams at critical points throughout the facility. Practical experience shows that matching equipment capabilities with actual site conditions prevents headaches down the road.

Throughput Volume and Workflow Demands

The amount of material moving through the system and how work gets done day to day really matters when picking out truck unloading gear. Start looking at what kind of volumes come through during busy periods so we can find machines that won't bog down under pressure. Make sure whatever equipment makes sense fits into current operations without causing bottlenecks somewhere else in the process. Check out different models side by side, paying close attention to specs that matter most for moving bulk materials quickly. Looking at what other facilities in related sectors have found successful gives us a good benchmark too. Seeing actual results from places facing similar challenges tells us a lot about whether certain equipment will deliver on promises versus just marketing hype.

Budget and Total Cost of Ownership

When looking at truck unloading equipment, creating a realistic budget and knowing what it really costs over time matters a lot. Begin by setting aside money for buying the equipment plus getting it installed properly. Then think about what happens after purchase too - how much will repairs cost? What about the workers needed to operate it? And don't forget those unexpected days when something breaks down and stops production completely. Take a good look at different ways to pay for the equipment and calculate how quickly it might pay itself back through improved operations. Many businesses miss this part entirely but factoring in actual savings from faster loading times or reduced waste can completely change how worthwhile an investment seems in the grand scheme of things for their bottom line.

Common Types of Truck Unloading Equipment and Their Applications

Forklifts and Powered Industrial Trucks

Forklifts play a really important role in all sorts of loading and unloading situations because they handle pallets and big items so well. These machines can lift and transport heavy stuff with pretty good accuracy, which works great whether inside warehouses or out in shipping yards where space is tight. There's actually quite a few different kinds of powered trucks on the market today designed specifically for varying weight limits, so no matter what kind of cargo needs moving, there's probably a forklift up to the task. Modern models come equipped with safety tech like stability control systems and automatic brakes that make operating them much safer than older versions from just a few years back. Keeping these machines running smoothly requires regular checkups too. Mechanics need to look at things like hydraulics and tire wear regularly to avoid breakdowns during critical operations when time matters most.

Conveyor Systems for Automated Handling

In busy warehouse settings, conveyor systems play a key role in making things run smoothly with their efficient automation capabilities. They speed up the unloading of goods while cutting down on the need for workers to lift and move items manually, which naturally boosts productivity across the board. Different kinds of conveyors exist for various jobs – belt conveyors work great for lighter items, roller systems handle heavier loads better, and chain driven models excel at moving bulk materials through tight spaces. When warehouses integrate these systems into their current operations or connect them with other automated equipment, they see real improvements in workflow efficiency. The whole operation flows much better without those annoying slowdowns at critical points. Regular upkeep is essential though; keeping conveyors running properly ensures they continue streamlining the unloading process day after day without unexpected breakdowns disrupting operations.

Dock Levelers and Lift Platforms

Dock levelers really matter when connecting trucks to loading areas, making sure goods move across without problems. The lift platforms help get things transferred safely even when there's height differences between vehicles and docks. For these systems to work properly, safety matters a lot too. Hydraulic controls need to be good quality and materials should hold up under regular use. Most companies find that keeping up with regular maintenance makes all the difference for their dock levelers staying functional day after day. A little attention goes a long way towards preventing breakdowns and keeping operations running without interruptions.

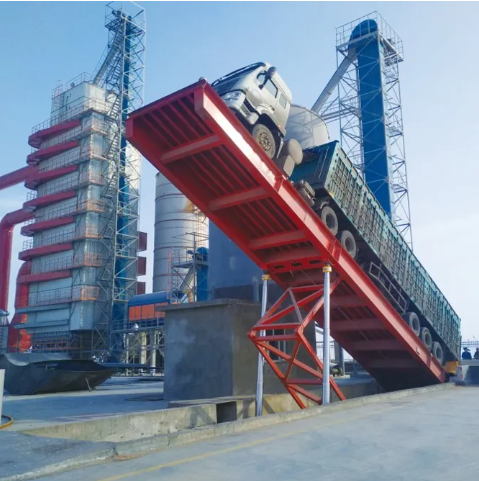

Specialized Container Unloading Solutions

Container unloading systems that specialize in different cargo types help streamline operations across various industries. Modern facilities now rely on things like automatic cranes and hydraulic lifts to get containers off ships faster while keeping workers safe from injury risks. The real advantage becomes apparent when moving dangerous goods or delicate equipment, where even minor mistakes could lead to serious consequences. For instance, chemical plants need these specialized setups to meet OSHA standards for transporting corrosive substances. Looking at how ports implemented these systems shows just how much difference proper technology can make. Companies that invested early saw improvements not only in speed but also in reducing accidents during loading and unloading cycles.

Safety and Compliance Requirements for Efficient Operations

OSHA Regulations and Industry Standards

Following OSHA rules matters a lot when dealing with materials handling and unloading operations around the worksite. When companies stick to these guidelines, they actually cut down on accidents and injuries at work places, which makes everyone's day safer overall. Industry standards also come into play here too, especially when operating those big machines used for unloading trucks. Take OSHA's latest changes for instance they've beefed up their regulations about how dangerous materials should be handled, adding all sorts of new safety protocols that workers need to follow. Companies that handle truck unloading really need to keep track of these updates if they want to dodge fines from regulators and most importantly protect their employees better than before.

Built-In Safety Features in Modern Equipment

Today's unloading gear comes packed with safety tech that keeps workers safe on the job site. Take automatic brakes for instance they kick in to stop any unexpected movements while stuff gets unloaded from trucks or containers. There are also overload sensors built right into the machines these little gadgets sense when something too heavy is loaded onto the equipment, cutting down on accident risks before they happen. The way these machines are shaped matters too. Manufacturers have been focusing on ergonomics lately, so operators don't get as tired or hurt their backs after hours of work. This means jobs get done faster without compromising worker well being, which is pretty much what everyone wants in this business.

Operator Training and Maintenance Best Practices

Good operator training remains essential if we want to keep unloading equipment running safely. The best training covers all the basics really well including how to handle equipment controls, understand safety rules, and know what to do when something goes wrong on site. Maintenance work cant be ignored either because regular checks cut down on equipment failures and keep things running smoothly day after day. Proper maintenance records are actually pretty important too since they show regulators that standards are being met and often catch small problems before they become big headaches. With new tech coming out all the time, continuous learning matters more than ever. Operators need to stay current with newer models and features so everyone stays safe at work.

Industry-Specific Considerations for Equipment Selection

Food/Pharmaceutical Handling Requirements

When it comes to food processing and pharmaceutical manufacturing, picking the right equipment matters a lot for meeting those tough sanitation rules everyone has to follow. Companies really need to think about how they can stop contamination from happening in the first place. That means going for gear that doesn't collect dirt easily and stays in good shape over time. Cleanliness should be at the top of the list when designing facilities. Materials matter too since some just don't hold up well against strong cleaning agents or rust over time. Stainless steel makes sense for many applications because it doesn't have tiny pores where bacteria could hide, plus it stands up pretty well against most microbes. Look around any modern facility and chances are good there will be things like special conveyors designed for hygiene or lifting mechanisms with tight seals that keep unwanted particles out during production runs of delicate items.

Heavy-Duty Needs in Manufacturing and Steel Industries

Manufacturing plants and steel mills need tough unloading gear to handle all those massive shipments they deal with daily. The machinery has got to take a beating without breaking down since these facilities move tons of material back and forth constantly. When talking shop about what matters most, folks always bring up load capacity numbers and how fast cycles complete themselves. These factors really affect how much gets done each day on site. Operators run into problems when containers get too big or materials weigh more than expected. That's why many facilities invest in heavy duty equipment upfront instead of patching together cheaper alternatives later. Good quality machines cut down on breakdowns and keep production lines moving smoothly through even the toughest shifts.

High-Speed Demands in Retail and Logistics

The retail and logistics sectors run at breakneck pace most days, which means warehouses need gear that gets stuff off trucks fast without wasting time. E-commerce has really cranked things up lately, so getting products from warehouse to customer door faster than ever before isn't just nice to have anymore it's basically table stakes now. Companies are turning to tech solutions like those AGV robots we see zipping around distribution centers and upgraded conveyor belts that handle multiple SKUs simultaneously. These upgrades cut down on delays caused by manual handling mistakes too. When orders start piling up during holiday seasons or flash sales, having reliable automation makes all the difference between meeting delivery promises and watching angry customers switch brands. Warehouse managers know this well they spend hours evaluating different equipment options because picking the wrong system can sink an entire operation when demand spikes unexpectedly.

FAQ Section

What factors should I consider when choosing truck unloading equipment?

Consider factors such as load type, weight capacity, facility layout, dock configuration, throughput volume, workflow demands, budget, and total cost of ownership.

What are some common types of truck unloading equipment?

Common equipment includes forklifts, powered industrial trucks, conveyor systems, dock levelers, lift platforms, and specialized container unloading solutions.

How does compliance with OSHA regulations affect truck unloading?

Compliance with OSHA regulations is crucial to prevent workplace accidents and ensure safe operations in truck unloading processes.

Why is equipment selection important in the food and pharmaceutical sectors?

Equipment selection is vital in these sectors to ensure compliance with strict sanitation and safety standards, minimizing contamination risks.

How do technology innovations impact the logistics industry?

Innovations such as automated guided vehicles and advanced conveyor systems help optimize productivity and meet the high-speed demands of the logistics industry.