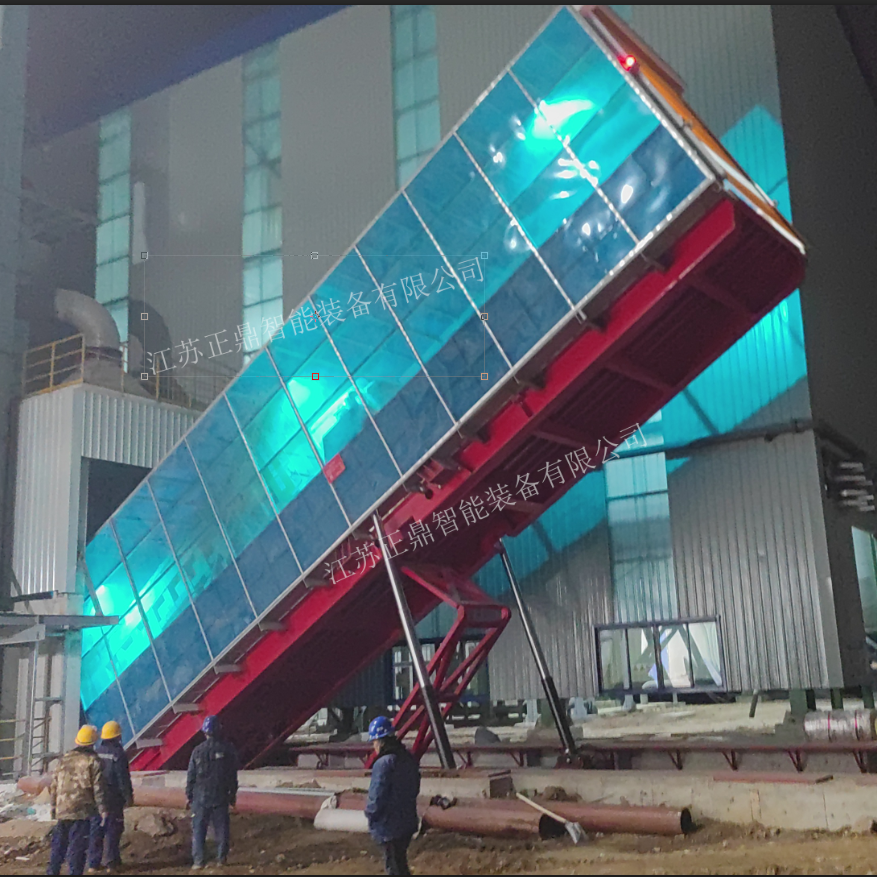

truck bed gravel unloader

The truck bed gravel unloader is an innovative material handling solution designed to revolutionize the way bulk materials are discharged from truck beds. This sophisticated system combines robust engineering with practical functionality to deliver efficient and controlled unloading of gravel and similar materials. The system typically consists of a hydraulically powered conveyor mechanism that can be mounted directly onto the truck bed, featuring adjustable speed controls and precise material flow regulation. With its advanced safety features including emergency shutoff systems and overload protection, the unloader ensures both operator safety and equipment longevity. The system's versatility allows it to handle various aggregate sizes, from fine gravel to larger stones, while maintaining consistent flow rates. Its modular design enables easy installation and maintenance, with components that can be quickly accessed and serviced when needed. The unloader's intelligent design incorporates weather-resistant materials and sealed bearings, ensuring reliable operation in diverse environmental conditions. This equipment has found widespread applications in construction, landscaping, road maintenance, and various other industries where efficient material handling is essential.