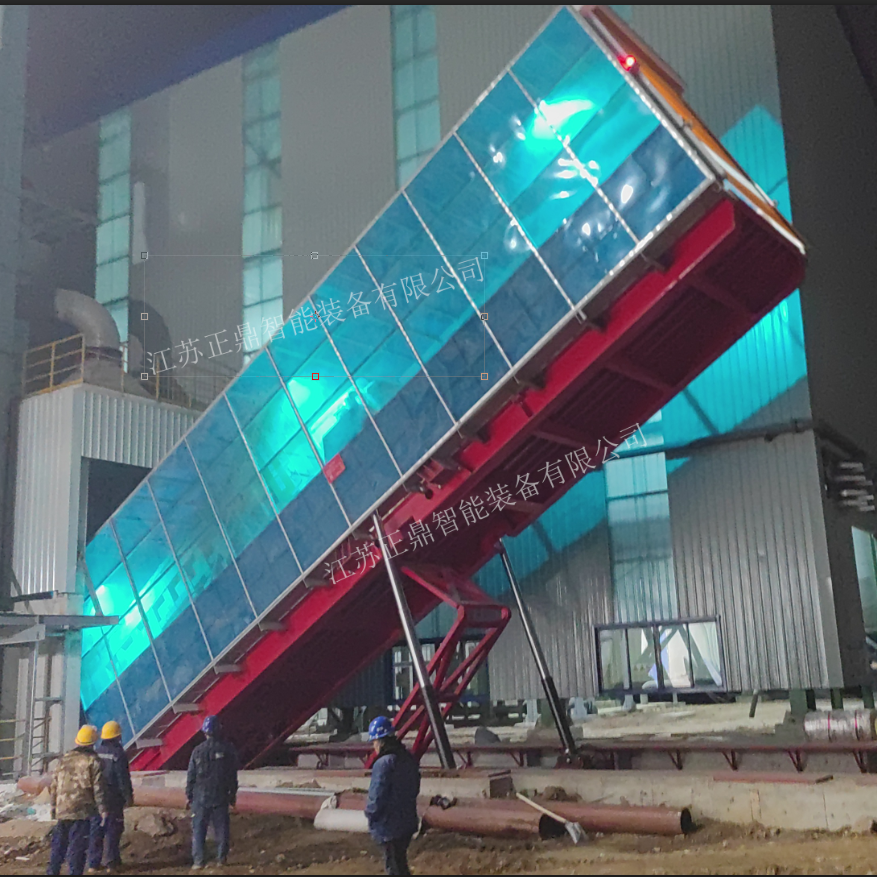

dump truck tipper

A dump truck tipper is a sophisticated piece of construction and transportation equipment designed to efficiently handle bulk material handling operations. This versatile system consists of a hydraulic mechanism that enables the truck bed to be raised at one end, allowing for the controlled discharge of materials such as sand, gravel, construction debris, and other loose materials. The modern dump truck tipper incorporates advanced hydraulic systems that provide smooth and precise control during the dumping process, ensuring safe and efficient material discharge. The tipper mechanism typically operates through a multi stage hydraulic cylinder that can lift heavy loads at angles ranging from 45 to 70 degrees, depending on the specific model and application requirements. These systems are engineered with robust safety features, including stability control mechanisms, load sensors, and emergency stop functions to prevent accidents during operation. The design incorporates high strength steel construction, reinforced pivot points, and wear resistant surfaces to ensure durability and longevity in demanding work environments. These vehicles are essential in various industries, from construction and mining to waste management and agriculture, offering reliable performance for material transport and disposal operations.